Always a fundamental element of a sustainable supply chain, the traceability of Prosciutto di San Daniele concerns every stage of production. Increasingly digitalised, through QR Codes and databases, it enables the end consumer to choose a safe, healthy, excellent and high quality food product.

The Prosciutto di San Daniele sector has been operating for over thirty years in favour of transparency and acts to ensure that consumers are assured all of the necessary controls and verificationsof the manufacturing process of Prosciutto di San Daniele DOP, a sustainable, certified, safe and traceable product.

To this end, since June 2019, the Consortium has directly managed the digitalised traceability systemsby means of a proprietary application for the printing of a unique QR Code placed on each tray of pre-sliced Prosciutto di San Daniele.

The digital tracking system enables consumers to access, in real time, via a smartphone, all the information regarding the entire production, specifically: origin of the raw material, duration of maturation, slicing date, ingredients, weight, place of maturing and slicing.

Packaging thus also takes on an active role as a guarantee of the origin, value and typicality of the product.

In order to guarantee an even more efficient traceability system thanks to innovative IT applications, two new projects have recently been launched.

The San Daniele Portal, which starting operating in 2018, is a digital cloud database that operates in real time, dedicated only to producers, created to collect all the documentation relating to the production of San Daniele PDO.

Furthermore, in 2023, access to the San Daniele Portal will also be made available via mobile devices.

Meanwhile, since 2021, in partnership with other entities, testing has started on an RFID support affixed directly during the slaughter phase to the fresh thighs used to produce PDO hams, collecting all the data and information, making it immediately available to operators in the supply chain, by using a simple barcode reader.

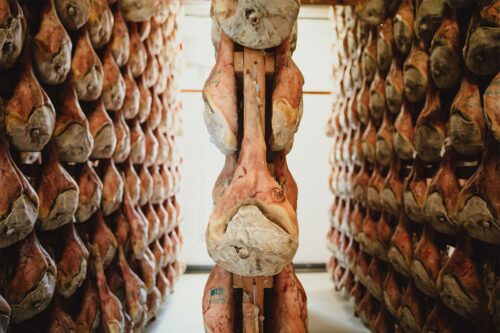

The traceability of Prosciutto di San Daniele, in addition to the QR Code shown on pre-sliced packages, is also possible via three signs affixed to the pork thighs.

In fact, the Production Regulations provide that, within the thirtieth day of the pig’s birth, both legs are tattooed with a unique code identifying the farm, the place and the month of birth of the pig.

In the slaughterhouses, after the appropriate checks, a further heat stamp bearing the slaughterhouse identification code is imprinted on the thighs.

Lastly, in the ham factories, all hams are marked with the processing start date, certifying their entry into the San Daniele DOP circuit and, at the end of the maturing process, after passing the strict checks carried out by the control body, the branding takes place with the Consortium brand, showing the manufacturer’s identification code.

Distinguished, since its foundation, for its operational approach focused, partly, on the product’s sustainability, in 2019, the Consortium approved its own Excellence and Sustainability Model, a document last updated in February 2023, named “Tangible Value”, in which the four pillars of the sustainability of San Daniele are identified: environmental protection, animal welfare, nutrition and food safety and traceability of the supply chain.

“Even the new Prosciutto di San Daniele Regulations” states Mario Emilio Cichetti, General Director of the Consortium “maintains the traditional breeds of Italian heavy pigs as the basis of the PDO and further clarifies the possible cross-breeding combinations between them. The document, which maintains rigorous controls along the entire supply chain, ensures increasingly greater quality, healthiness and traceability of the ham from the farm to the table, starting from feeding, to the slaughter age of the pigs, to also intervene on the new cured ham qualitative assessment parameters. In fact, the new Production Regulations also took inspiration from the technological-production evolution underway and already consolidated in the current PDO production, such as the extension of the minimum maturation period and the reduction of the use of salt in the salting of hams, in order to obtain a product that is even more in line with the needs of healthy and correct nutrition”.

The production of San Daniele involves all operators in the PDO supply chain.

Firstly, starting from the selection of suitable Italian Large White, Italian Landrace and Italian Duroc breeds, breeders must attend to all phases of growth, feeding and development of the pigs, from lactation to fattening. During every stage of their activity, breeders, as well as slaughterers, are also required to fulfil the legal health obligations defined by the Italian State, compliance with which is verified by the veterinary services via official controls that monitor animal health and well-being on farms and slaughterhouses.

The Consortium that defines the production criteria, although it does not directly intervene in the activities of farms and slaughterhouses, is committed to promoting animal welfare, for example, by raising awareness amongst farmers, encouraging them to apply good breeding practices and promoting a reduction in drug use. In this regard, the Consortium immediately joined the National Quality System for Animal Welfare, the inter-ministerial decree issued jointly by the Ministries of Health and Agriculture, Food Sovereignty and Forestry, which is an online tool with the highest standards in terms of sustainability.

The main objectives of the regulation are to ensure food quality and the economic, social and environmental sustainability of the production processes of the livestock sector, to improve animal health, reduce environmental emissions and provide consumers with correct information on animal welfare.

“Given the demand from consumers for increasingly greater clarity on the supply chain,” adds director Cichetti, “the Consortium positions itself as the leader of a transparent production process at every stage of production according to the requirements of theProduction Regulations, the correct application of which is verified by IFCQ Certifications srl, a third-party and independent control body authorised by the Ministry of Agriculture, Food Sovereignty and Forestry”.