Prosciutto di San Daniele is the result of a slow process in which time plays a key role. It is the product of an ancient artisan tradition punctuated by a series of crucial steps which make San Daniele PDO the protagonist of the Made in Italy brand, for which it is appreciated worldwide.

Over the centuries, the production of Prosciutto di San Daniele has remained virtually unchanged: only the advent of technology has enabled the processing to be systemically improved, making it increasingly safe and efficient.

As dictated by the Product Specification, Prosciutto di San Daniele can only and exclusively be produced in San Daniele del Friuli – in the Consortium’s thirty-one prosciutto factories, in compliance with the rules laid down.

The production of San Daniele PDO is strictly linked to the territory and its historical and geographic heritage. The ideal conditions for ageing the pork legs are created by a combination of the town’s location and its particular microclimate, made unique by the meeting of the warm currents blowing from the Adriatic Sea and the cooler, drier currents coming from the Carnic Alps, whilst the Tagliamento river acts as a natural thermoregulator. Pork legs, together with sea salt, are the only two ingredients allowed in the production of Prosciutto di San Daniele and are precisely what give it the extraordinary excellence for which it is known.

Arrival of the hind legs at the prosciutto factories and cooling

The legs, from pigs born, raised and slaughtered in certified farms located in the ten regions in Northern and Central Italy, as laid down by the Product Specification, must be delivered to the prosciutto factories within five days of slaughter and must not weigh less than 12.5 kilograms and no more than 17.5 kilograms, with a good ratio of lean mass to fat layer.

As soon as they reach the prosciutto factory, the legs are subjected to a preliminary conformity check: all those with aesthetic of physiological defects are not used in the production of San Daniele PDO. Once past this preliminary phase, the workers label the legs with the processing start date, necessary to precisely calculate the duration of the maturation.

After this check, the legs are transferred to designated cold rooms so that the meat reaches a temperature of 0°C. This is an absolutely essential procedure in order to prepare the meat for the following processes.

Trimming

At this point the legs are ready for the next phase of processing: the trimming, which consists of the elimination of the excess fat and muscle from the inner thigh. In this way, its possible to correct any imperfections in the cut and, at the same time, facilitate the penetration of salt into the meat.

Salting

Sea salt, as mentioned above, is one of the ingredients in Prosciutto di San Daniele. The Specification stipulates the exclusive use of sea salt applied to saturated salt solution that acts as the only preservative of the prosciutto; in fact, San Daniele PDO is free from additives, nitrites and nitrates, therefore constituting a natural product.

During the salting phase, the thighs, once covered with salt and laid out on a horizontal surface, are arranged in a designated cold room where they rest for a period equal to their weight (one day for each kilogram), thus the salting is balanced in relation to each thigh. In doing so, the meat begins to lose its excess moisture and the drying process is initiated.

Pressing

In this phase of the processing, the prosciutto legs are placed one on top of the other, compressing the thighs, allowing the salt to deeply penetrate them so as to impart that characteristic and strong flavour, stimulating the loss of internal fluids and giving it its texture.

Rest

At this stage, the thighs must rest. The resting takes place in rooms with a humidity between 70% and 80% and with a temperature that hovers between 4°C and 6 °C. This phase lasts until approximately the fourth month after the start of the processing. In doing so, the salt reaches the core of the thigh, distributing itself evenly.

Washing and Drying

Once the rest period is over the thighs need to be refreshed. Therefore, they are washed with warm water so as to eliminate external residues and agents and put to dry in a room whose temperature varies from 15°C to 24°C, to ensure perfect drying.

Smearing

After being properly washed and dried, the thighs are ready for the next phase, the smearing. The ‘sugna’ is a mixture of pork fat, rice flour and salt; the rice flour is used to make the prosciutto completely gluten-free and therefore, also suitable for coeliacs. The ‘sugna’ is applied to the rindless part of the thigh which makes the surface layers of the meat softer, therefore preventing it from being excessively dry and stringy.

Ageing

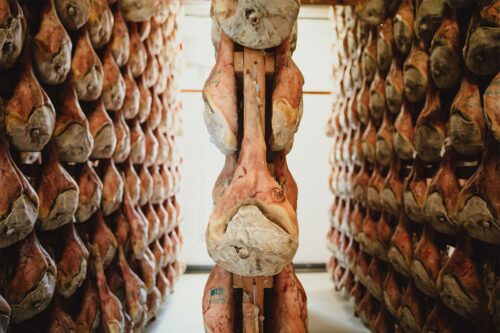

The phase, considered to be the most delicate and important phase of the whole production process of Prosciutto di San Daniele, now begins: the ageing. The thighs are hung up inside designated rooms with large windows that allow the winds that lap San Daniele del Friuli to cradle the thighs and, at the same time, the humidity to balance the rooms’ microclimate. Here, thanks to the completely unique temperature and humidity conditions, the enzyme processes that impart the characteristic aromas and unmistakeable flavour begin in the meat.

The thighs are placed in the rooms in the fourth month from the start of the production process and, as stipulated in the Product Specification, they stay there for a minimum of four hundred days. It therefore needs plenty of time to become Prosciutto di San Daniele as we know it and it only becomes so after a long period of rest and slow maturation.

Piercing

Piercing is an essential procedure to assess the progress of the maturation. A type of needle carved from a horse’s femur is inserted into the thigh to evaluate the aromas and texture. Upon having carried out this assessment, its very important that the hole drilled is resealed with the ‘sugna’, so as to prevent external agents from settling in the meat.

Branding

Once the four hundred days of maturation have passed, the prosciutto is examined. The supervisory body, IFCQ Certificazione, carries out controls that verify the prosciutto leg’s compliance with the requirements laid down by the Product Specification: only the prosciutto legs that meet all parameters are certified and branded with the Consortium’s mark.